What can Thermoplastic Hoses be used for?

What can Thermoplastic Hoses be used for?

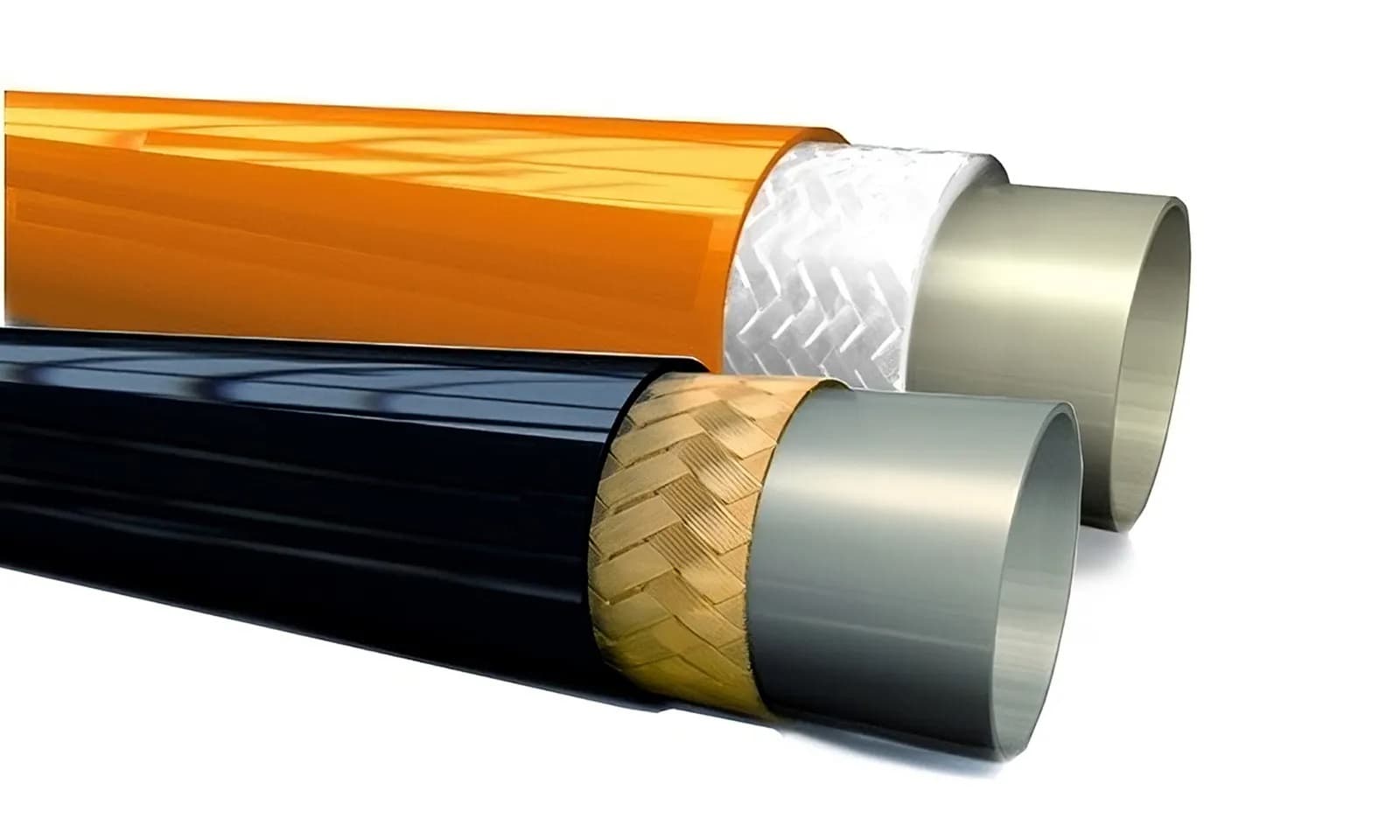

Thermoplastic hoses are designed to be able to handle very high temperatures. Generally, thermoplastic hoses are constructed with high level of contact strength between the layers of tube, reinforcement, and cover. This high level of contact is generated because thermoplastic materials can be re-melted during the production process, allowing for both a chemical and a mechanical bond. The inner tubes of thermoplastic hoses are generally manufactured from plastics such as polyamide, polyester, and fluoropolymers. The specific polymers used in the hose depend on design factors like pressure capability, compatibility with the fluids to be conveyed, operating temperature range, abrasion resistance, and the ability to resist degradation from chemicals, solvents, cleaning fluids, saltwater, ozone, and UV radiation. Thermoplastic hoses are generally manufactured with one or two layers of reinforcement that provide strength and pressure resistance. These reinforcement layers are typically braided and made from materials like polyester fibers, polyamide fibers, or steel wires. One of the most important factors in the construction of the thermoplastic hose is how the tube, reinforcement, and cover layers are bonded together. Thermal and chemical bonding methods ensure strong adhesion between the layers because thermoplastic materials can be re-melted during the production process.

Thermoplastic hydraulic hoses are different from generic hydraulic hoses in that they are designed to withstand extreme temperatures and environmental factors that would prematurely degrade rubber hose. As a result of the manufacturing process, thermoplastic hoses also have a self-supported inner tube that is cured without a mandrel. Because of this manufacturing process, thermoplastic hoses can be made in extremely long lengths - some continuous hoses are up to 8,000 meters long.