Dual Ferrule Compression Tube Fittings

DUAL FERRULE COMPRESSION TUBE FITTINGS

Leaks in hydraulic hoses can be expensive and dangerous. Slow leaks cause slippery surfaces and compromise the efficiency of equipment, while large leaks can shut down an entire job site.

Many leaks and equipment failures occur at the fitting site. This is why it is important to always use the proper fittings with each hose type. The fittings should be installed correctly and checked regularly.

DUAL-FERRULE TUBE FITTINGS

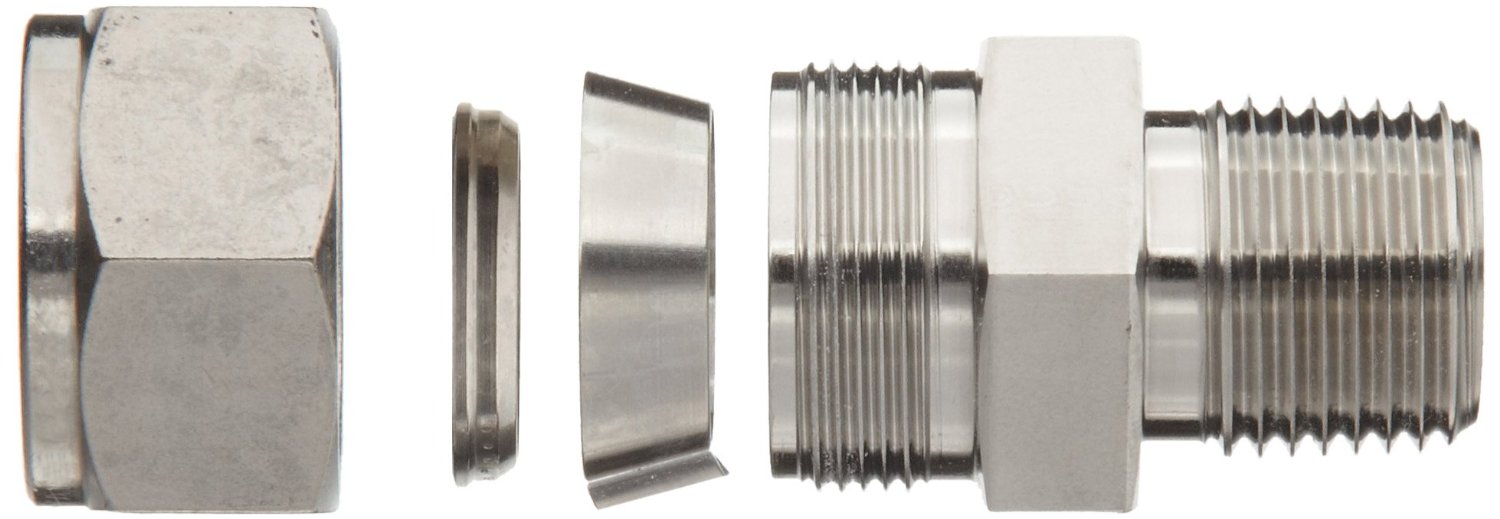

A dual ferrule tube fitting is often preferred over a single ferrule. A dual-ferrule fitting has 4 parts that, when combined with the tube itself, create a 5-part joint that is more likely to remain leak-free.

These four pieces are the nut, a front and back ferrule, and the body of the fitting. The ferrules attach to the outside of the tube, creating a firm grip when the nut is tightened without collapsing the inner tube. This allows the installer to tighten the nut fully, ensuring a tight seal.

Some fittings are constructed to eliminate torque as the fitting is installed. This lessens potential damage to the hose itself. The ferrule configuration also helps to overcome some variance in tube thicknesses, although care should still be taken to match hydraulic hoses as closely as possible.

QUALITIES OF DUAL-FERRULE TUBE FITTINGS

High-quality dual-ferrule tube fittings will be reliable in all of the same environmental and work-site conditions as the hoses themselves.

TEMPERATURE

Dual-ferrule tube fittings should be able to resist fluctuations in temperatures caused by environmental variance as well as from heat created by machinery. The seal should hold steadily at whatever temperatures the hoses are rated for. As the temperature cycles, the seal should remain steady.

PRESSURE

Many hydraulic hoses are used under fluctuating pressures, with occasional bursts of high pressure. Failure of a fitting at this stage can be catastrophic. Dual-ferrule tube fittings should outlast the hoses themselves, resisting any pressure. The tube should burst before the fitting does. They should not be compromised no matter how many times they are pressurized and then released.

ADAPTABILITY

Despite your best efforts, there will be some differences in the hoses joined by fittings. A good fitting will be able to seal properly regardless of minor variables in tube construction and materials. It should also be able to seal properly without crushing the tube or compromising the flow of fluids.